My 1994 Boss Hoss - Godzilla

|

My seventh motorcycle - a 1994 Boss Hoss

My Boss Hoss was my final "real bike" purchase. My "actual" last motorcycle purchase was a 1982, 650 Honda "Crash Bike," purchased for $100.00. I purchased this bike for my girlfriend of that time period so she could learn to ride. Since the bike was so cheap, ugly, and a Honda, I figured it would be a much better learning tool than an expensive new bike. I purchased that bike sometime in 1999 for $100.00. Did I mention it was $100.00? Anyway, I may post more information and pictures of that bike down the road. Now back to the Boss Hoss...

I originally heard about Boss Hoss V8 motorcycles around 1995. Even back in '95 I knew I just had to have one. I didn't actively seek one out until I test rode a Boss Hoss at the 1996 Sturgis, South Dakota biker rally. After test riding one, I absolutely knew I had to have one!

While at Sturgis I ran into a guy named Tony, who just happened to be selling his Boss Hoss. Tony was living in Washington state and apparently had a balloon payment due on some land or somesuch. Needless to say he was desperate for cash so the Boss Hoss had to go. I approached Tony about possibly trading my new Dyna Wide-Glide for the Boss Hoss. He was pretty uninterested in a trade at that time. If anyone recalls, H-D waiting lists were at their peak around that time period, so Harleys were in pretty high demand. I tried to convince Tony that it would be much easier to sell a Harley rather than a Boss Hoss because a Boss Hoss is a highly specialized motorcycle for the insane-at-heart, whereas a Harley could be sold to just about anyone. At the time Tony was convinced he had to have cash, but I got his phone number anyway and vowed to call him every few days until he sold his bike to either me or somebody else. About 2 weeks later Tony finally said, "Okay...let's do this. I'm going to need some cash in addition to your Harley." I had already gone over this in my mind. I had decided that I would be willing to pay $1,000.00 (in addition to my Dyna Wide-Glide) and not a penny more. I conveyed this to Tony and he agreed to $1,000.00. The gears were in motion.

The original plan was to meet Tony in Las Vegas, Nevada, halfway between Albuquerque and Washington (remember Tony resided in Washington state). I would then ride the Boss Hoss 600 miles back to Albuquerque. I had a couple friends living in Vegas, so Vegas was a perfect meeting place for me. I could cut my travel expenses by staying with friends there. Unfortunately, as they say, even the best laid plans... Apparently Tony's truck broke down in Northern Nevada (he was trailering the bike) so I ended up riding an additional 300 miles to meet him. The rest is history.

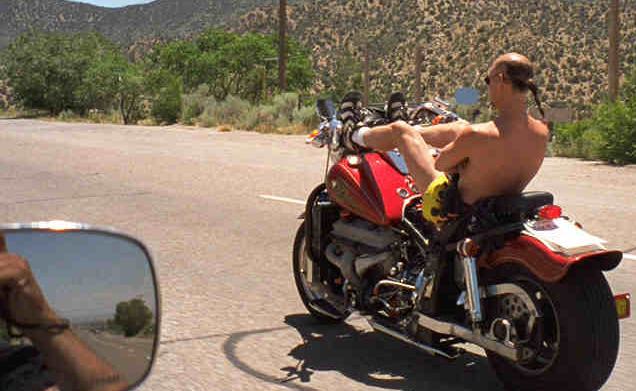

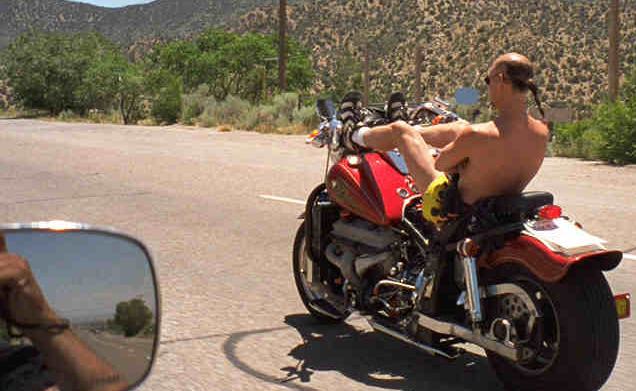

Here's some pictures of my Boss Hoss about 6 month after I got her.

Though Tony had the foresight to build the bike with all top-of-the-line components, the bike had many issues. For one, I couldn't stand the way the gas tank cantilevered up (see above picture). The tank was not only aesthetically displeasing, but access to the carburetor required removal of the gas tank. This was unacceptable since the Holley 650 Douple-Pumper requires frequent rebuilds. Not only that, but access to the air filter was near impossible, requiring removal of the tanks and terminal block (the red board with all the wires attached to it, as seen below), which segues us to another issue; the electrical system.

Instead of using the frame as a ground, Tony ran individual ground wires to everything. This was not only a waste of wire, but caused a huge spaghetti wire mess all over the bike, especially under the gas tank. Wires were run to fuse blocks that did nothing. Removing all fuses initiated no state change in the bike's electrical system. The bike continued to run and function perfectly with no fuses - not good.

Another thing I couldn't stand were the handlebars. Their ergonomics (or lack, thereof) forced my hands into an awkward position which made an already difficult-to-ride bike even more difficult to ride. I fantasized about having the only Boss Hoss in the world with Ape-hangers...ahhhh, to dream...

Around November of 1999 I started racing the Boss Hoss at the drag track. Unfortunately I didn't do so well, as I had geared the Boss Hoss tall to be more highway-friendly. In one of my runs excessive wheel spin caused the Boss Hoss to come around on me. True to my racing instinct I stayed into the throttle to avoid a "high-side" situation. For those not in the know, a "high-side" is caused when the rear wheel regains traction while the rear end of the bike is out to either side of the rider. In theory, as long as you stay into the throttle the rear wheel should not gain sudden traction, but should eventually correct itself - in theory. Unfortunately lady luck was not shining on me that day and the rear wheel continued to come around until I could no longer keep the bike in an upright position. Consequently I crashed. I was okay, but enough damage was done to the bike that I had to trailer her home.

The Boss Hoss sat under a tarp for nearly 3 years while I purchased parts and contemplated repairs. The frame suffered minor damage that would require the skills of a gifted welder to repair correctly. Not trusting just anyone to the task (including myself), it took roughly 3 years to find a welder that I not only trusted, but that had their own mobile welder that could be brought to my house. Fortunately my vocal coach's son offered to help. He did a killer job!

The Boss Hoss was now on it's way to total repair! In addition to minor aesthetic fixes, I had to replace the clutch.

In the wreck the clutch had somewhat exploded into what I like to call, "Clutch Soup."

Of course a major part of the "Boss Hoss rebuild project" was cleaning up the wiring mess. I was able to remove the terminal bus board completely as seen in the picture below. Hey look! There's a carb under there!

The picture below is what the tank looked like before I split it.

By cutting the middle section out of the tanks, I was not only able to expose the carburetor without having to remove the tanks, but I was able to remount the tanks so that they laid down parallel to the valve covers instead of on that hideous angle (see below).

With the tanks, wiring, and Ape-hangers in place, I was now faced with the dilemma of mounting all the gauges. I stole the solution for this problem from my friend,

Dave Campos

(the other guy in town nuts enough to use a Boss Hoss as an everyday rider). He shaped a piece of polished aluminum to fit the space between his tanks. Once drilled, the aluminum section could be used to house gauges, switches, and whatever else I would need. I liked the idea so I stole it (with his permission, of course).

Below is a picture of Dave holding his homemade dash board. Note the frame and engine on the floor in front of him. That mass of parts is the frame and Shovelhead engines used to set his 322 mph world land speed record, set in 1990. His record still holds as of this writing.

To emulate Dave's idea I had to first appropriate a rectangular section of aluminum. However after doing some experimentation with polishing compounds on aluminum and stainless steel, I decided to go with stainless 'cause I could get it to look a little more like chrome. So my first task was to purchase a hunk-o-stainless.

I polished it for hours and hours...

...to a mirror like finish...

...and then farmed it out to Mike at Gearheads to have it cut and bent to my specifications.

Here's a picture of the test fit prior to drilling the holes for the gauges and switches. She fit like a glove. Good job, Mike!

The only thing left to do now was to drill the holes...

...mount the gauges...

...and wire them up!

The finished product!

She was now ready for the road!

She is now an everyday rider. Admittedly I ride my Harley more than I ride my Boss Hoss, except during the winter months, that is. In the winter I prefer the Boss Hoss because of the excessive amount of heat that eminates from the LT-1 350 C.I.D. Corvette engine. My legs and toes stay warm and toasty.

In the above picture Godzilla (my Boss Hoss' name) is donning a 235/75R15 rear tire. Since then I have installed a 255/65R15. I may post pictures of the new rear tire at a later date.

Note the cute license plate. Can you tell what it says?

If you have any questions, comments or suggestions, please e'mail me.

Go back to "Motorcycles" page.

|